Solder Paste Viscosity. Impact on PCB Soldering. Defects

Author Dmitrii KhramtsovPosted 11 November 2025

Updated 11 November 2025

Hi. Have you ever noticed that some solder pastes get a perfect soldering, while others, similar, get bridges and defects? In this article, you will understand why solder pastes viscosity is to blame.

Solder paste viscosity in electronics manufacturing is very important. Why it’s essential to choose solder paste with the right viscosity index by Malcom for your specific tasks. And what kind of defects you will face after PCB reflow if you ignore this parameter.

Solder Paste Viscosity Types.

It’s very simple: the lower the viscosity index, the more fluid the solder paste. The higher the viscosity index, the thicker the solder paste.

For dispensing with syringes or needles, low and medium viscosity solder pastes with a Malcom viscosity index from 900 to 1800 are best, as they flow more easily through dispensing needles. Low and medium viscosity solder pastes are used also for high-speed printing, where the PCBs quickly passes through soldering ovens on SMT line.

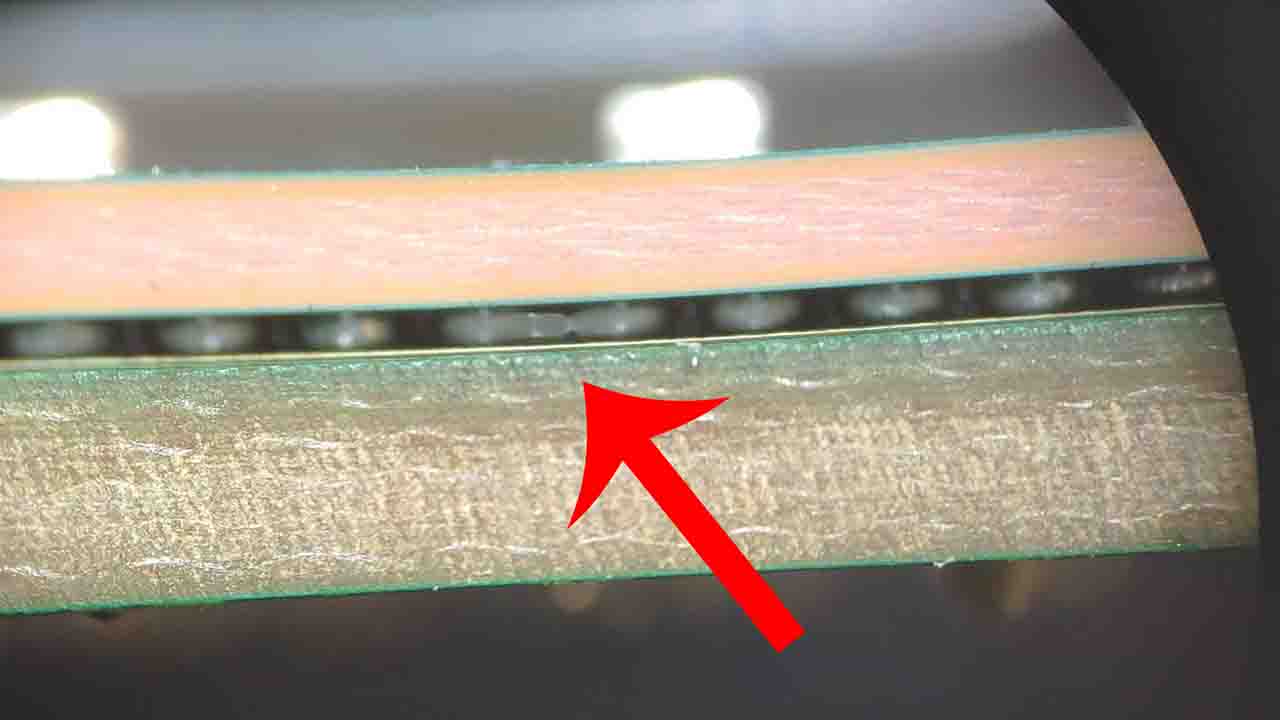

Low and medium viscosity solder pastes have poorer shape retention. The higher room temperature, the faster the solder paste loses shape and spreads between PCB pads.

For stencil printing, it’s better to use a solder paste with a Malcom index of at least 1800. The solder paste printed through a stencil can maintain its proper shape for hours without spreading. That’s why it’s important to keep the right room temperature — between 21 and 25 °C for all types of solder pastes.

Where to Find the Viscosity Value.

The viscosity index is rarely indicated on solder paste datasheet. If you can’t find the datasheet for your solder paste online, you should think about what kind of trash you’re planning to use for soldering your PCBs. Because the datasheet must be published for all kind of that products.

Serious PCB assembly manufacturers use Indium, Kester, AIM, and some others solder pastes, which must be stored in the refrigerator and mixed before use.

What determines the viscosity of solder paste?

The viscosity of solder paste directly depends on the flux it contains. Soldering flux has a limited shelf life - 1 or 2 years, and flux properties deteriorate faster if stored improperly — on its own or as part of the solder paste.

That’s why it’s very important to mix the solder paste every time before use. During long storage, the flux can separate into fractions, so the paste must always be thoroughly mixed.

If soldering paste stored incorrectly, some important components may evaporate, and the quality of the flux inside the solder paste will degrade significantly — which will affect to soldering quality. This is why it’s important to follow the expiration date indicated on the jar.

Defects due to incorrect Solder Paste Viscosity.

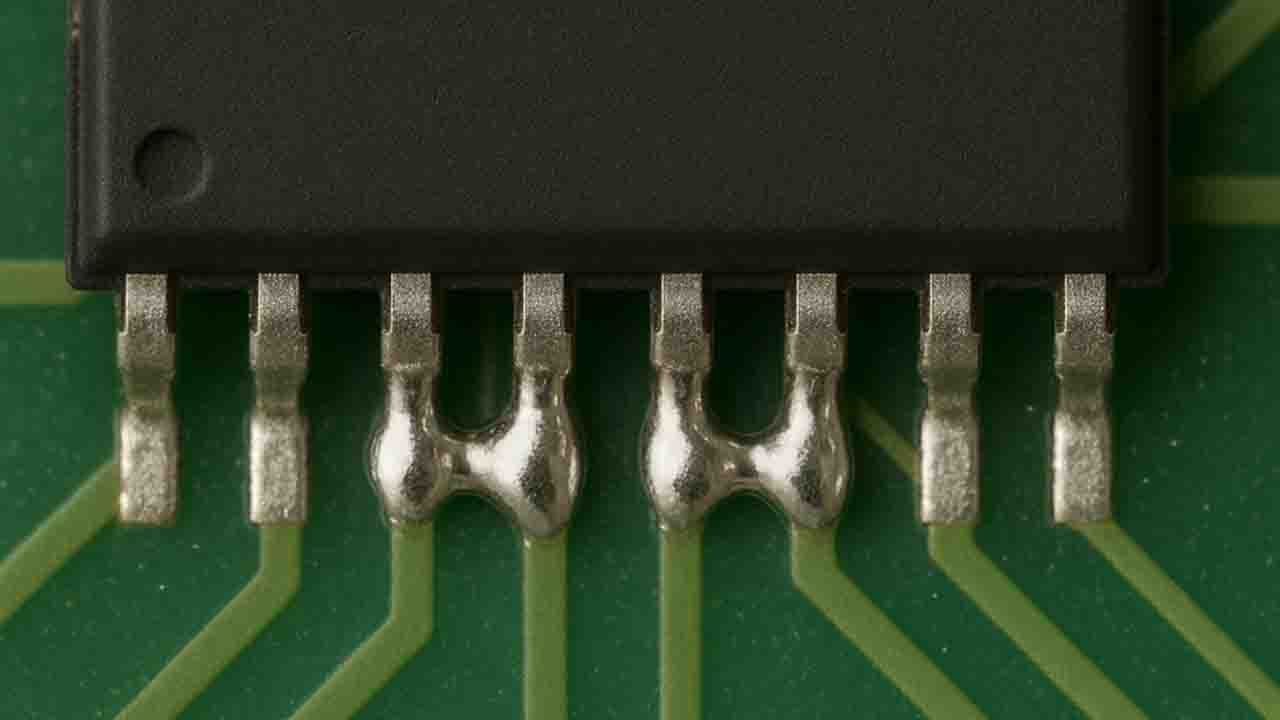

A common defect when using low and medium viscosity solder paste for stencil printing is solder bridges between pins, pads or deposits.

You will be very disappointed if you install BGA chips on a low viscosity solder paste — once the balls under the BGA chip stick together, you can’t fix it. You will have to remove the BGA chip and repair the PCB.

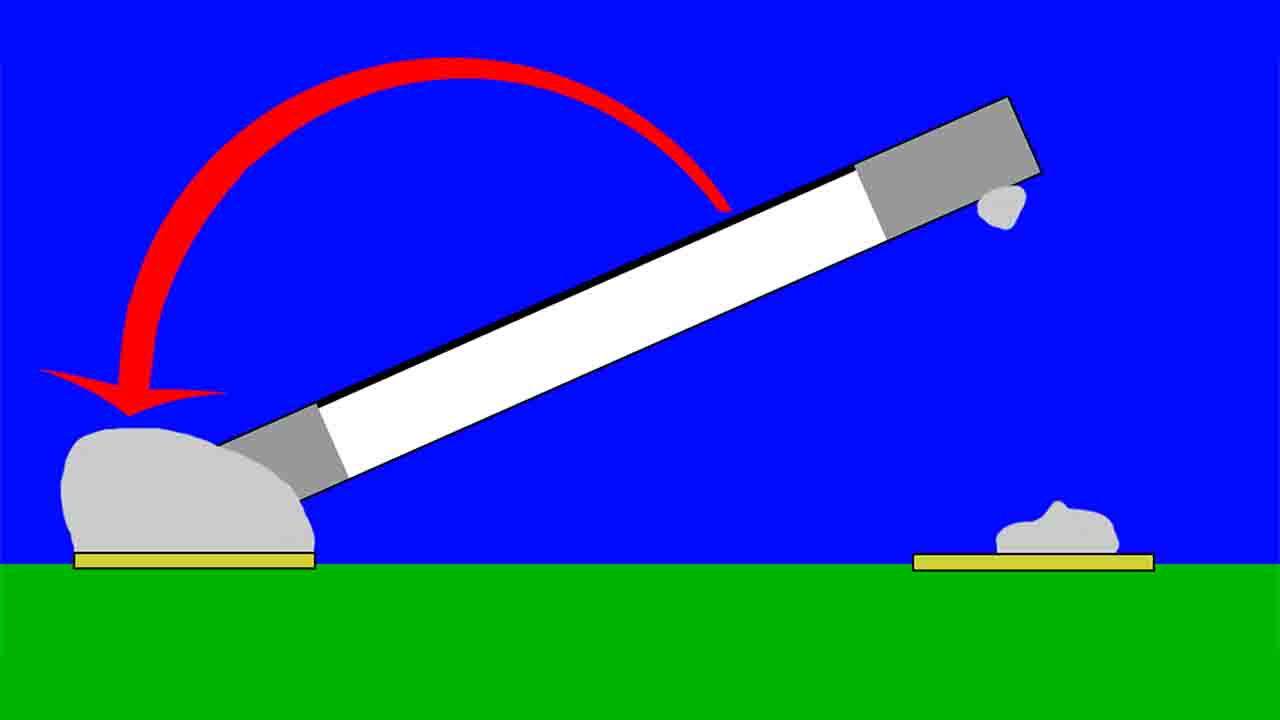

Another defect is the transfer of solder paste volume to adjacent pads. You will get different amounts of solder paste on same PCB pads, which leads to tombstone defects after melting and further rework. Additional article about TOMBSTONE EFFECT.

Why is the Solder Paste Viscosity not indicated on cheap Jars and Syringes?

A big problem is when people buy solder paste and don't realize that viscosity is a key parameter. Chinese manufacturers of cheap solder pastes on popular marketplaces don’t mention the viscosity index at all.

For the DIY segment, manufacturers omit this parameter so that people don’t worry about unnecessary but very important details. The main goal is just to make people buy, not to care about quality or usability.

As a result, people form a completely wrong understanding of solder paste and how to work with it. I have heard many discussions about which solder paste people “like more” — liquid or thick, and how to make solder paste thinner after long storage.

They completely ignore the real criteria that matter in professional electronics manufacturing. Just in case, additional article about SOLDER PASTE

Thank you for reading!

Watch video Solder Paste Viscosity — The Real Cause of Defects!