Electronic PCB Moisture Protection. Varnish Coating Methods

Author Dmitrii KhramtsovPosted 20 May 2024

Updated 27 June 2025

Many devices, from dishwashers to military drones and defense systems, use conformal coatings to protect printed circuit boards from moisture and other environmental effects. How to apply the coating so that it does not crack in the cold and does not peel off after a month?

I will talk about PCB preparation, coating application methods, common mistakes, and what’s actually worth using in practice. I’ll explain why even a good coating can fail if the PCBs is not properly prepared or the coating is not applied correctly.

Part 1. What is electronics moisture protection and why is it needed?

Moisture protection is the application of an insulating coating layer to a printed circuit board. The purpose is to prevent aggressive environmental conditions and moisture from affecting the operation of electronic components and to extend the life cycle of the device.

In addition to coating the PCB, sealants are also used to completely encapsulate the enclosure containing the PCB. A clear example is electronic control units in vehicles, but this is a more complex option.

Coatings are easier to apply and allow fast processing of large batches. However, sometimes full encapsulation is strictly required. Full encapsulation serves to fix components in place, especially heavy ones that can detach due to vibration or mechanical shock - for example in vehicles, aerospace systems or industrial equipment.

Potting with compound prevents this and also protects the device from moisture and environmental exposure.

Part 2. Key principles of working with moisture protection coatings.

1. Air bubbles in the layer are a defect.

If air bubbles remain after coating, protective properties are reduced. Moisture can be trapped in the bubbles, which may freeze at negative Celsius temperatures and cause cracks inside the layer.

Air Bubbles are removed using a vacuum chamber or by dipping the PCB into a very fluid coating. Use solvents recommended by the coating manufacturer.

2. Thick coating is not always good.

You should not apply more than two layers of coating. When the coating is too thick, it loses strength during rapid temperature changes from negative to positive and back. Every coating has a thermal expansion coefficient, and thick layers can crack and even damage or detach components. Ideal when apply two thin layers with proper drying in between.

3. Test PCBs with coating in a thermal chamber if possible.

Even one properly applied layer can crack at –65°C or -85°F. If the device is critical, test coated PCBs in a thermal chamber. I have performed such tests. The thick layer cracked, while the thin layer remained intact and protected the PCB.

4. Never apply coating on a dirty PCBs.

Before applying coating, PCBs must be cleaned in a professional cleaning system. Residues of any soldering fluxes and other contaminants interfere with adhesion, which over time can cause the coating to peel. Adhesion is the bonding properties between different materials.

5. Always work under a fume hood.

Not just a filter—use a proper fume hood designed for this work - ducted chemical fume hood. The hood should have a dedicated exhaust duct to the outside, and the ventilation system should ensure fresh air supply to maintain air balance.

6. Coating behavior at low temperatures.

If the PCB operates in freezing conditions, it’s better not to use the dip coating method, as the coating may shrink in the cold and damage solder joints by pulling on and detaching components. But at high temperatures, the coating can soften or melt - this also needs to be considered.

7. Spot-mask for protection connectors.

Connectors and some contact pads must be protected—taped off or covered with a spot-mask. A spot-mask is a gel that’s inert to metals and becomes rubbery, allowing the coating to be applied and then the spot-mask removed, leaving components cleaned.

I recommend testing the spot-mask on the connector first before applying moisture protection. There have been cases where the spot-mask reacted with the connector metal and caused oxidation on surfaces. In such cases, find a different manufacturer.

8. Read IPC standards.

The IPC-CC-830 standard defines requirements for conformal coatings, while IPC-TM-650 includes testing methods such as adhesion and thermal cycling. These documents form the basis for the protection of electronics.

Part 3. Methods of applying moisture protection coating.

Method 1: Applying conformal coating with a brush.

The simplest method. Bubbles are common. One issue is that brush bristles can fall out and get stuck in the coating layer, making them hard to remove.

Method 2: Fully dipping the PCB in coating.

The coating should be very fluid, like water, to ensure an optimal, thin layer. The board is fully submerged in the coating for about 1 minute. During this time, the coating flows under components and displaces air bubbles.

After removal, allow the coating to drip back into the container. Boards are dried vertically on hooks in a fume hood or in a specially designed drying system.

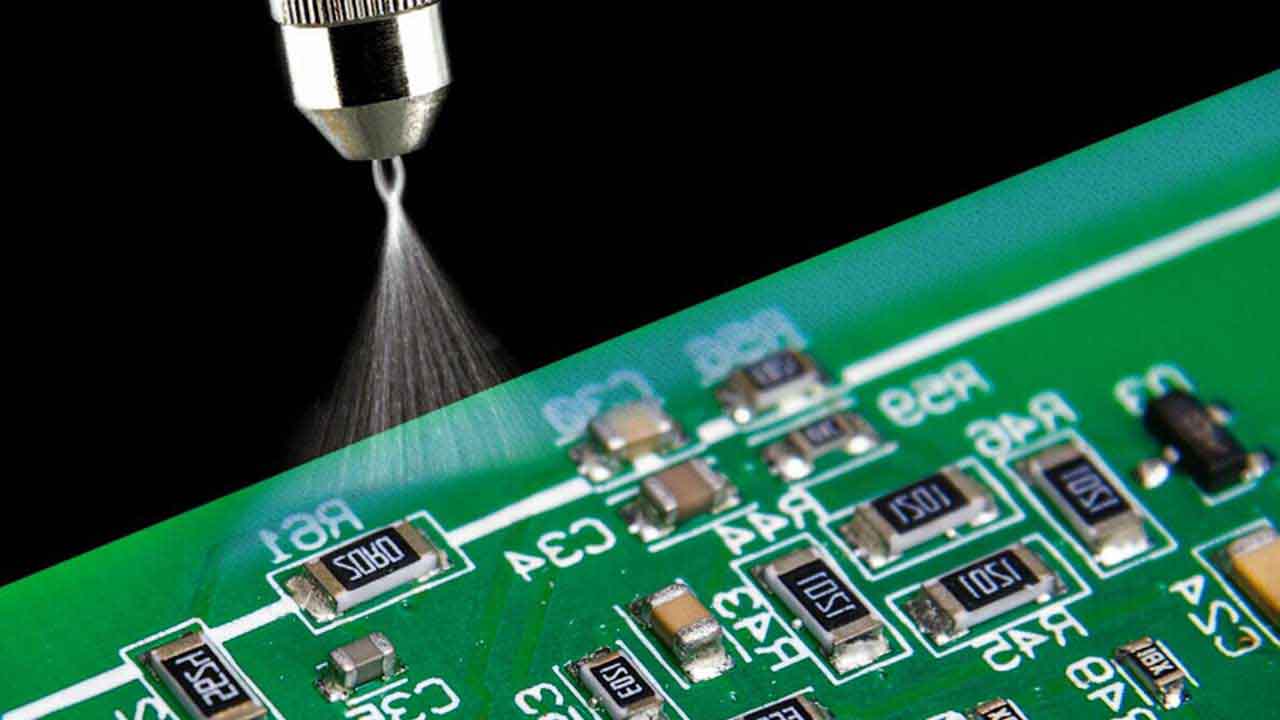

Method 3: Robotic conformal coating application.

The fastest and most precise method used in PCB productions. Robot apply the coating only to specific areas, avoiding accidental contact with connectors and places that should be without varnish.

Method 4: Varnish spray can or manual sprayer.

A fast and convenient method for small batches and post-repair protection. The varnish coating is applied quickly, multiple layers can be added, but it’s difficult to control uniformity.

Part 4. Solvents for varnish.

Each type of conformal coating—acrylic, silicone, urethane, or epoxy—requires its own solvent, listed in the datasheet, on the sticker, or on the manufacturer website. Don’t use random solvents, this may cause separation, poor adhesion, or incomplete curing. You will just ruin the varnish.

In conclusion …

Properly applied conformal coating is not a small thing. It’s what ensures your PCB doesn’t fail due to condensation, moisture, cold, or dust. It’s especially important for critical electronic devices.

Thank you for reading!

Watch video about Electronic PCB Moisture Protection and Varnish Coating Methods!