Express 24 LLC

A small company with BIG Ambitions

Location: Hallandale, Florida

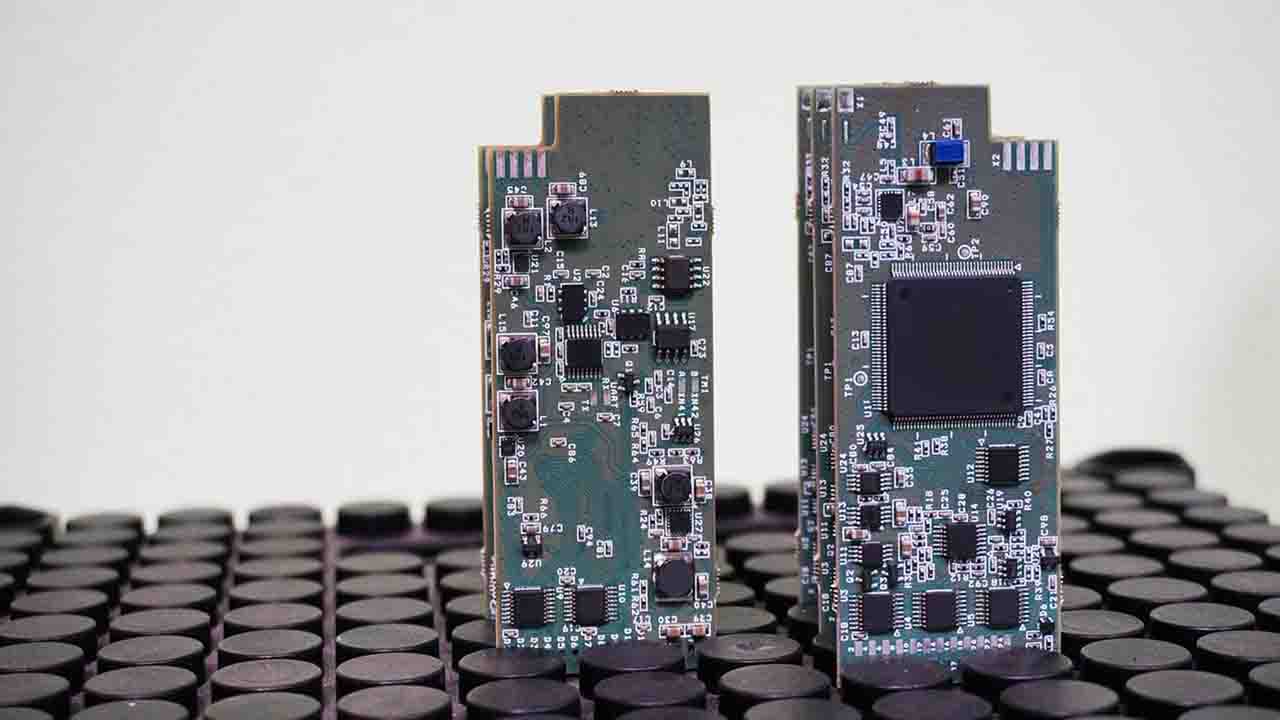

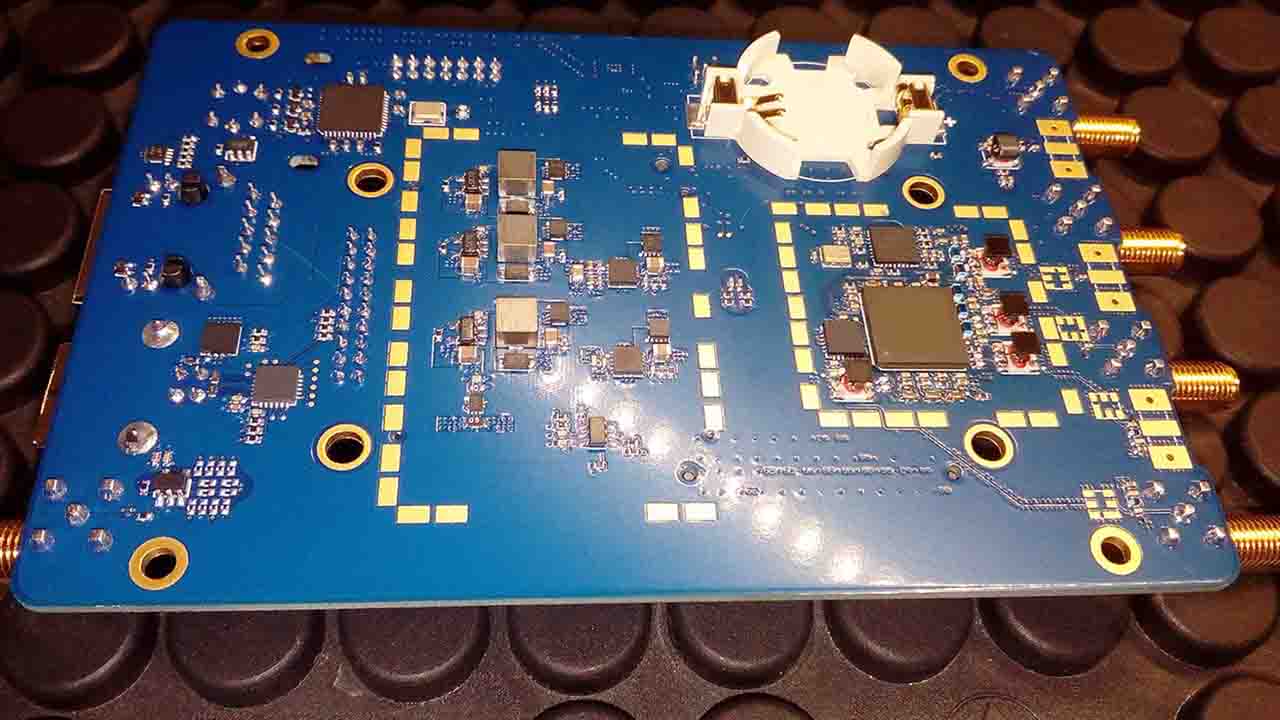

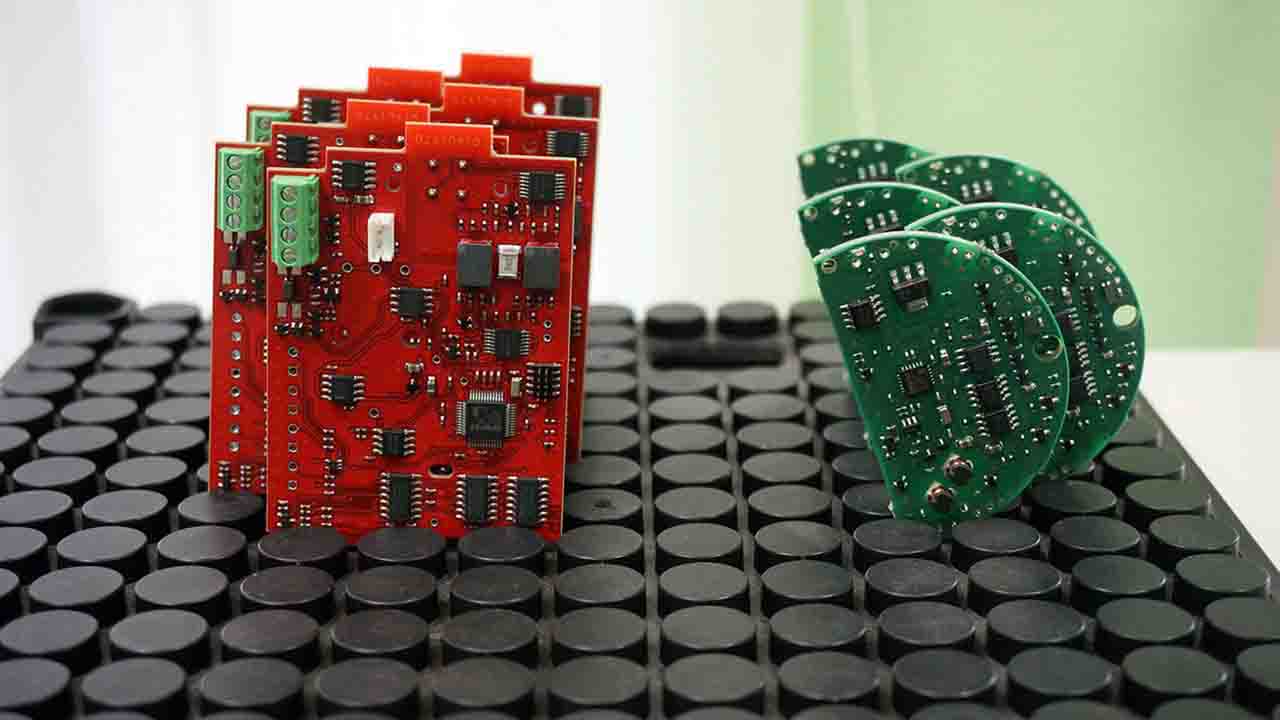

PCB assembly process covers both SMD and through-hole soldering methods. Components are placed with high precision to ensure stable electrical and mechanical connections. All soldering operations follow IPC-A-610 and J-STD-001 standards, guaranteeing long-term reliability. We work with both lead-free and leaded alloys depending on customer requirements. Every solder joint is visually inspected and verified under magnification to prevent cold solder joints or bridging, ensuring consistent results for both PCB prototypes and serial production.

We assemble printed circuit boards with components ranging from 0201 to large QFP and BGA packages. Accurate alignment and temperature-controlled reflow soldering ensure proper wetting and melting. We use high-quality no-clean ROL0 soldering fluxes and solder pastes. The reflow profile is optimized individually for each board design to minimize thermal stress. The result is a stable and repeatable SMT manufacturing process suitable for high-density electronic assemblies.

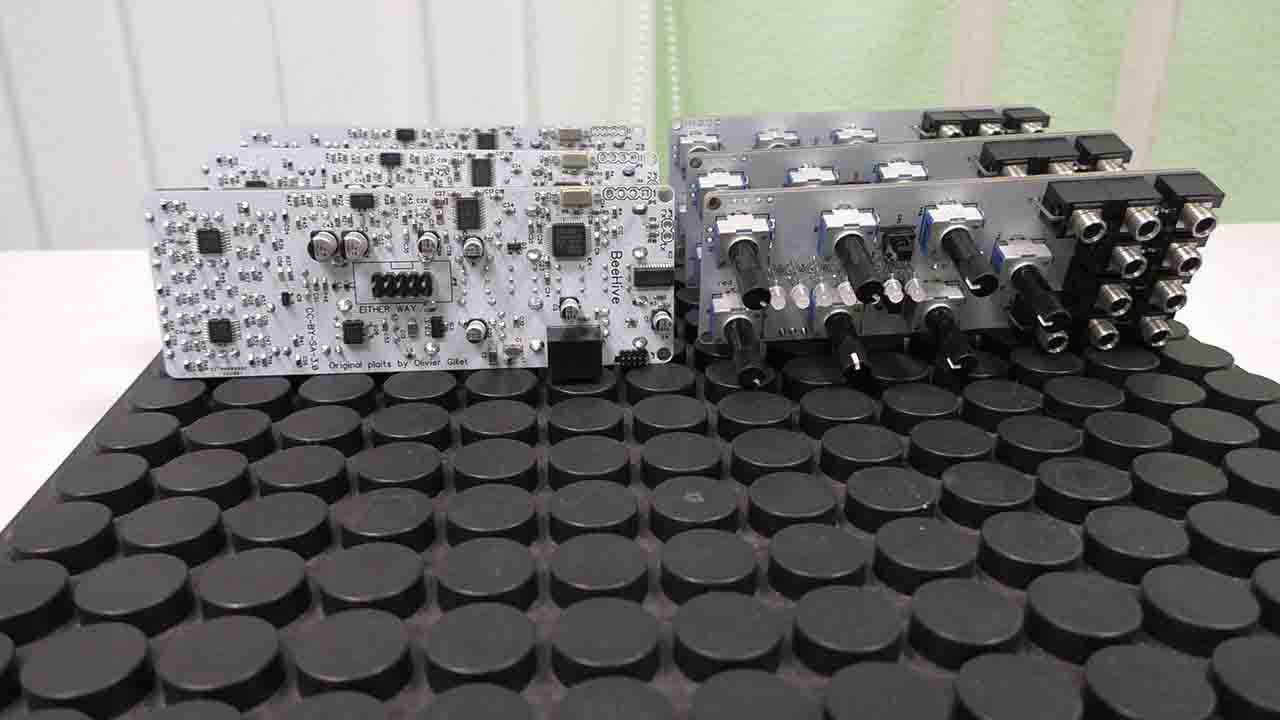

We perform through-hole (DIP) soldering using both manual and wave soldering techniques. Our operators are trained and certified according to IPC standards. The process includes precise lead trimming, soldering, and cleaning. We work with components of all types and sizes — connectors, transformers, relays, passive and active components, and power modules. After soldering, each printed circuit board is inspected to confirm the quality of solder joints and the integrity of the assembly.

After soldering, each assembled printed circuit board undergoes a cleaning process to remove solder flux residues and ionic contaminants. We use aqueous and manual, non-ultrasonic cleaning methods. Deionized water and professional solvents ensure thorough cleaning and eliminate residues on fine-pitch components and under ICs. Drying and subsequent IPC quality inspection confirm the absence of contaminants and ensure long-term reliability.

Each batch of soldered PCBs is subjected to a detailed inspection and testing procedure. Visual inspection and microscope verification identify possible soldering or placement defects. Inspection ensures that the electronics meet design specifications before shipment. The entire workflow supports consistent quality and full compliance with IPC quality guidelines.

To enhance the reliability of electronic assemblies, we offer conformal coating and moisture protection services for all types of printed circuit boards. Protective coatings prevent corrosion, oxidation, and current leakage caused by moisture and contaminants. Depending on customer requirements, we apply acrylic, silicone, or urethane coatings using spray, dip, selective, or fill methods. Each coating layer is visually inspected to ensure uniform coverage and strong adhesion according to IPC-CC-830 standards.

Express 24 LLC provides professional PCB assembly services for industrial and commercial clients. We follow strict quality control procedures at every stage of production — from incoming component verification to final inspection and documentation. We assemble PCBs with any component type — SMD, through-hole, mixed, and fine-pitch packages. Consistent process control and adherence to IPC standards ensure the highest reliability for your electronic products. Each printed circuit board is fully inspected, cleaned, and ready for integration.

✅ We accept customer supplied PCBs, SMD and DIP components for assembling.

✅ We can purchase components in accordance with customer specifications, upon prepayment.

✅ Completed PCB functionality can be verified locally if appropriate test equipment is available.

✅ Specialized testing equipment and programmers for electronic modules must be provided by the Customer.

✅ PCB cleaning can be localized or full, depending on the request.

✅ Order completion times depend on the complexity and quantity of printed circuit boards.

✅ Payment is made before sending finished electronic modules to the customer.

✅ Service available only within the United States

✅ Shipping in both directions must be arranged and paid for by the Customer.

✅ Component ordering, cleaning, vacuum protection, and PCB testing are separate services that can be ordered separately or combined into a single order.