Why Electronics PCB Fail Early? Cheap vs Mission-Critical PCBs

Author Dmitrii KhramtsovPosted 2 October 2025

Updated 4 October 2025

Do you also feel that electronics have started breaking down faster? This is no coincidence!

Today I will explain why this happens.

Why do some electronic devices and PCBs fail very early while others can work for years without problems?

What determines the price?

How can electronic devices and PCBs failures be prevented at the PCB design and PCB assembly stage?

I will start with simple and obvious reasons and finish with serious problems.

Cheap Electronic Components for Assembly PCBs

Many manufacturers save money on electronic components during PCBs assembly. The same electronic components can be purchased at different prices, and their quality varies greatly.

Most companies produce mass-market electronics and don’t need expensive components. The most important thing for them is that the device works at least a little bit for the buyer. Buyer will buy a new one. This applies to almost any household devices. The main goal is profit for the seller.

A huge percentage of household electronics failures are related to manufacturing defects, not your usage, friends.

But there are also companies that value their reputation and create electronic devices meant to last for many years, where stability and long-term operation are very important. This can be mission-critical electronics for medicine, for military, space, automotive, and the aviation industry. Such electronics are often expensive, and this is not without reason, and here is why.

PCB Testing Cycle in Electronics Device Manufacturing.

There is no point in stress-testing millions of smartphones, TVs, or printed circuit boards for washing or drying machines. The manufacturer already knows that these devices are very fragile and often will not survive drops, extremely low or high temperatures—they overheat, cannot withstand high humidity and will begin to corrode.

However, for mission-critical devices and depending on operating conditions, printed circuit boards and assembled devices are subjected to a test cycle: most mission-critical PCBs are subjected to vibration testing on a stand—at different frequencies and intensities.

Thermal chambers are also used, in which a powered and functioning device is exposed to critical temperatures and sharp changes from –40 to +85 °C (32 to 185 °F) for 500 cycles. Admit it—not every device can endure that.

And it must be understood that all the electronic components on such PCBs must not change their characteristics significantly. Every electronic component can change its parameters at different temperatures, and the developer's task - to take this into account. A mission-critical device must operate properly at –40 as well as at +85 (32 to 185 °F), and some even at +105 (220 °F) and higher!

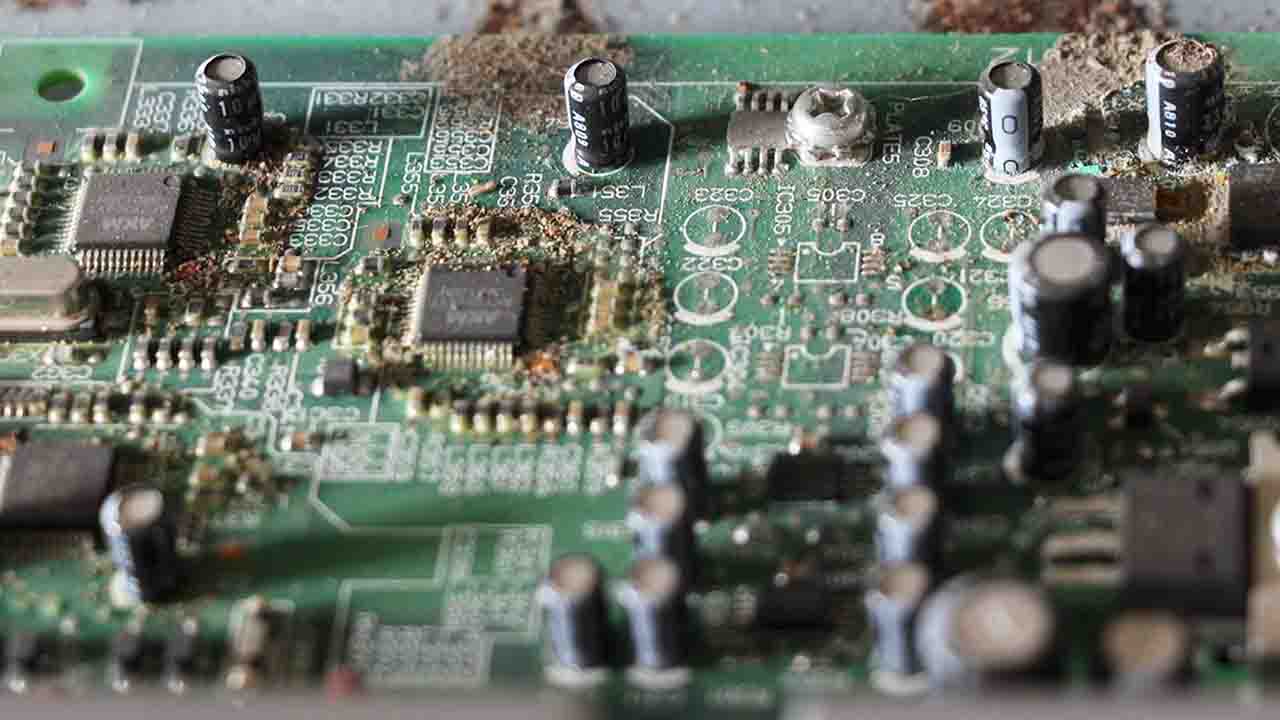

Electronics are also sometimes tested in dust chambers when device is intended to work in steppes and deserts. There can be tests in humid environments, in salty environments, in acidic environments, or providing radiation protection and tests for space or military use, when necessary.

For each device there are testing requirements depending on the operating environment, and these requirements are formulated before the development of the printed circuit board even begins. Important first step - Detailed Technical Specifications are written for the PCB and software developers. And from this point I move to the next topic.

Quality of Printed Circuit Boards Development.

Modern PCB design is not only about price. Some developers ask for big money, because of their ego, but in reality, they are not professionals in electronics development. This is very important to understand. You can get some sense of a developer’s level by looking at the devices they have designed.

Electronics developers who stand out are those working with serious FPGA systems, high-speed buses, high-frequency data transmission lines, video-signal processing, able to route complex multilayer PCBs with dozens of layers without signal-quality loss, developing complex mathematical operating algorithms, and so on. Such professionals are hard to find.

I don’t know a professional developers who has never reworked a newly created PCB. This always happens. When functional testing of the first release of PCB begins, mistakes always appear. The cycle of bringing a mission-critical PCB to the required condition sometimes takes several years. This is no joke. But functional testing is only the first step. The second parallel step is testing the newly created PCB for protection against external factors and temperature.

There is a rule:

Point 1. There are always mistakes in a device.

Point 2. If no mistakes are found in a device, see Point 1.

And then you look at a PCB and wonder why it costs so much money, while a Chinese copy is only a couple dollars. Only your responsibility is the decisive factor. What is more important — saving money OR safety and durability?

I don’t recommend attempting to repair critical expensive electronics that operate in cars, medical, and other critical devices. Many people treat this too superficially, but it concerns the people, who will be driving a car with a repaired ECU or repaired PCB inside an ABS system, or will be near a medical device where PCB has been repaired.

Any intervention and replacement on mission-critical printed circuit boards cannot guarantee the correct soldering of components, the absence of conductor damage, the use of original microchips, components, and materials that correspond to the operating modes. Who can guarantee the proper repairing and protection after opening such devices? — No one. Much is decided by the customer’s desire to save money and a complete lack of understanding of what is happening.

At the same time, developers of household electronics are not concerned with all these issues. For them, the operability of the first prototype often sufficient, which then goes into production. And as problems arise for users, developers will fix that problems. Here you have low prices, low-quality components, a small operating temperature range, poor PCB design and power circuits, a lack of static protection on PCB conductors, and a lack of any protection from external factors. And with all of this I move on to the next topic.

Electronic PCBs Corrosion and Lack of Moisture Protection

I recently discovered with surprise that the printed circuit boards inside some brands of washing machines have no protection from water. For me, this was a shock!

How long will a PCB last without moisture protection inside a washing machine? - Of course, not long! A one year or maybe two. Moisture will necessarily cause the conductors on the printed circuit board to corrode and become covered with gray traces of leakage between conductors.

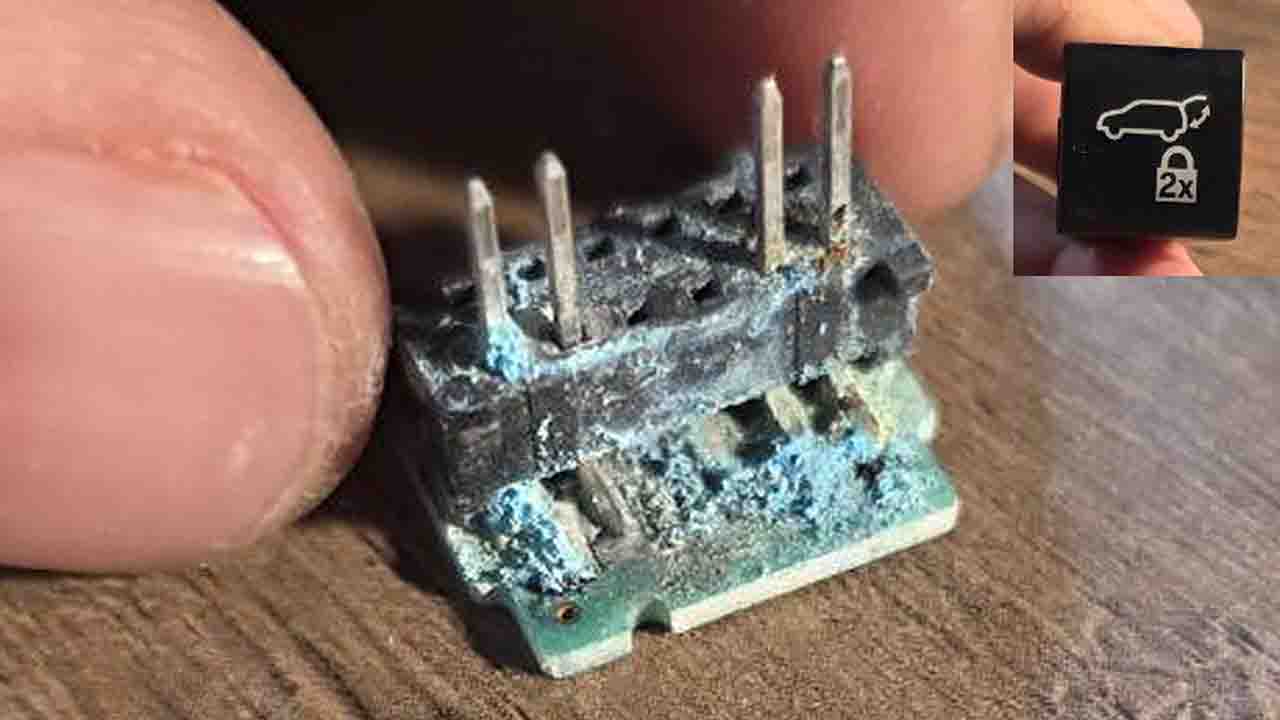

Moreover, there have been increasing cases of missing moisture protection in some car devices—buttons in doors and various modules inside the car. Saving on everything already affects vehicle electronics, and this is sad. Car manufacturers earn money on spare parts. This is no secret to anyone, but they have stopped providing even basic moisture protection for electronics inside! And how should proper moisture protection be implemented?

Mandatory coating with moisture-protective varnishes of all necessary areas of printed circuit boards, connectors and plugs from the housing must be rubberized and sealed. You can see such connectors under the hood of your car. But unfortunately, this approach is not applied everywhere inside the car.

On many cars even mission-critical modules are no longer protected at all, and they are located, as if on purpose, in those places and niches where water accumulates. In my opinion, this is an attempt to make money on spare parts!

Materials Used for Soldering Electronic PCBs

Having visited many manufactories in my life, I know that many companies don’t understand how to correctly use materials for soldering and protection. This concerns leaded and lead-free alloys, what temperatures and profiles are applied for different alloys, what fluxes should be used for everyday tasks and for repairs, also don’t understand how to clean electronic PCB after soldering. Now you know that many mistakes are created in the electronic manufactory and from developers before you purchase the device.

Watch video WHY ELECTRONIC PCB FAIL EARLY? CHEAP AND MISSION-CRITICAL DEVICES