Diamond Flux FN231 No-Clean ROL0

For Soldering and Repairing Electronic PCBs

Gel Soldering Flux in Syringe

Soldering Flux FN231 Description

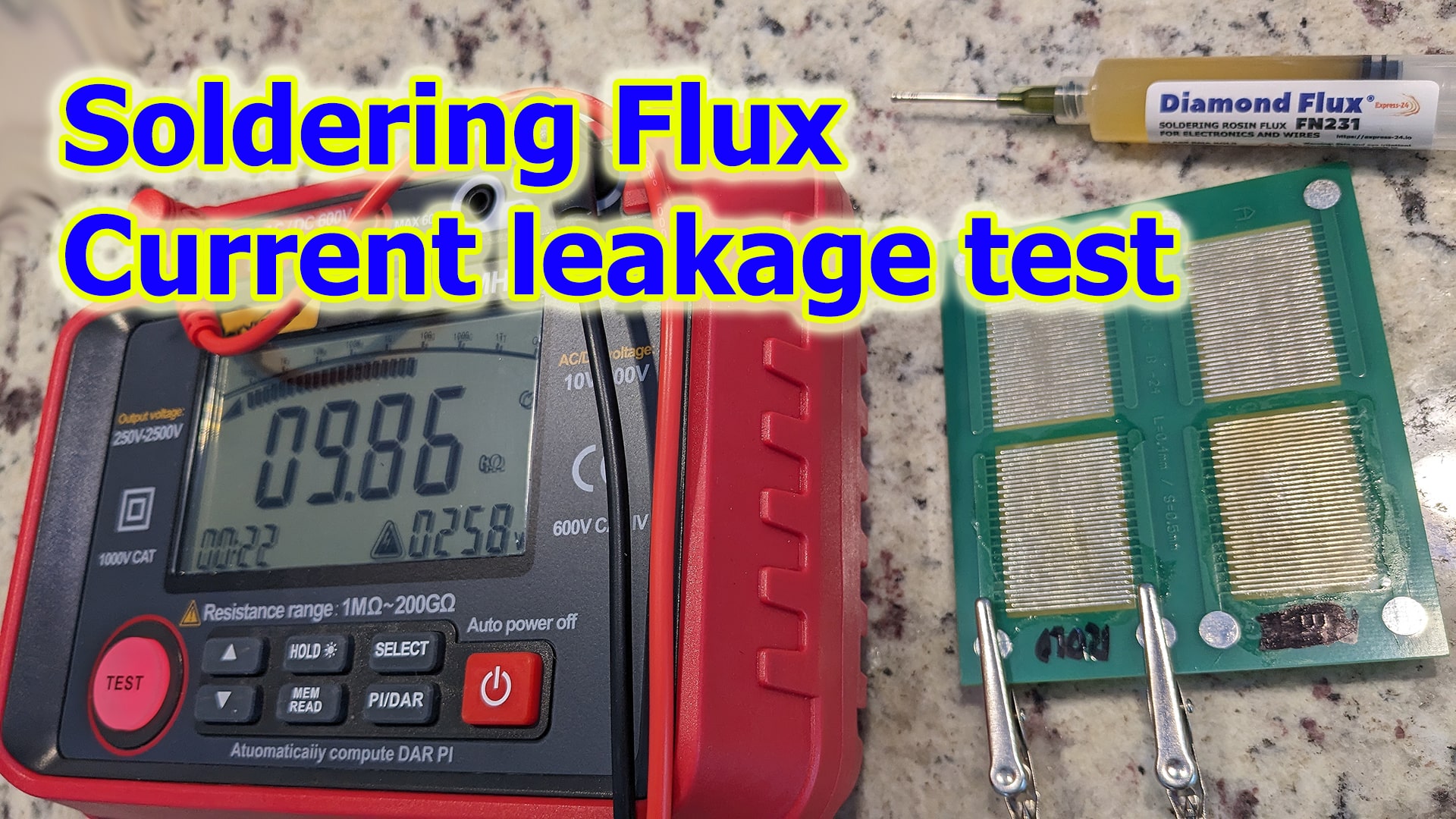

The Diamond Flux FN231 is manufactured in the Florida, USA, from organic components and Rosin. The soldering flux paste gel in syringe Diamond flux FN231 belongs to the class ROL0 no-clean, does not contain halogens. Residue after soldering does not cause corrosion on the printed circuit board(PCB), components and wires. Flux gel residue does not cause electrical leakage. The No-Clean PCB Solder Flux provides excellent wettability of soldered surfaces for better adhesion. Soldering flux is perfect for soldering any BGA, QFN, SMD, DIP, SOT and other electronic components.

Soldering flux for electronics Diamond Flux FN231 perfect washed off with any PCB cleaner.

Responsible soldering requires high-quality Fluxes!

The shelf life of Diamond Flux FN231 is 2 years from the date of manufacture.

Soldering flux for electronics Diamond Flux FN231 perfect washed off with any PCB cleaner.

Responsible soldering requires high-quality Fluxes!

The shelf life of Diamond Flux FN231 is 2 years from the date of manufacture.

Soldering flux FN231 Сharacteristics

Color: Amber

Class ROL0. No-clean

Boiling Point: 280°C

Softening Point: 70°C

Copper Mirror Test: Pass

Current Leaking Test: Pass

Phisical State: Solid Paste

Conforms to Standard J-STD-004B, ROHS

Low Activity Soldering Flux for Hidden BGA Pinout

Solder Flux Residue not Conducting, not Corrosive

Suitable for Soldering with Lead and Lead-Free Alloys

Good Wettability of Soldered Surfaces in the Production and Repair of PCBs

Suitable for Soldering - Repair BGA, QFN, QFP, SOIC Chips. For any SMD, DIP components

Not for Highly Oxidized Surfaces, Components and Boards. Use Soldering Flux for New Clean Surfaces

Class ROL0. No-clean

Boiling Point: 280°C

Softening Point: 70°C

Copper Mirror Test: Pass

Current Leaking Test: Pass

Phisical State: Solid Paste

Conforms to Standard J-STD-004B, ROHS

Low Activity Soldering Flux for Hidden BGA Pinout

Solder Flux Residue not Conducting, not Corrosive

Suitable for Soldering with Lead and Lead-Free Alloys

Good Wettability of Soldered Surfaces in the Production and Repair of PCBs

Suitable for Soldering - Repair BGA, QFN, QFP, SOIC Chips. For any SMD, DIP components

Not for Highly Oxidized Surfaces, Components and Boards. Use Soldering Flux for New Clean Surfaces

PCB Soldering, Wettability, Cleaning

Soldering

There is a printed circuit board on which the connector is soldered. Diamond Flux FN231 for soldering, connector. SnPb solder wire was used for soldering PCB.

Wettability

Before soldering the connector, a soldering flux paste gel Diamond Flux was applied to the place of soldering. The picture shows the result of soldering. Shiny solder joints!

Cleaning

Diamond Flux FN231 can be cleaned with industrial/manual water-based and alcohol-based PCB cleaners. Picture after cleaning with an alcohol-based spray cleaner.Soldering Flux Resistance Video and Table

Connectors Soldering Video

Documents

Soldering flux FN231 User Data Sheet

Soldering flux FN231 Safety Data Sheet

About soldering flux Diamond Flux FN231

Soldering flux paste gel for electronics Diamond Flux FN231 was obtained as a result of deep development and in the spring of 2023 the commercial product was ready to start sales. Development was carried out in Florida, Hallandale. It is also produced and packaged here.

The research lasted about 1 year with 17 serious experiments and an insane number of small tests were done.

To create a solder flux for soldering electronics, a number of requirements must be taken into account, and each requirement is very important.

Some of the requirements: No halogens, no current leakage, corrosion resistance, operating temperature range, boiling points, no smoke during soldering, toxicity indicators, harm to the environment and people, shelf life, easy cleaning and many other indicators that are no less important.

To achieve stable performance, it is necessary to carefully select chemical components, calculate formulas and molar masses. Each iteration of the soldering flux formula must undergo a series of checks and tests. The tests also require equipment that was purchased. Only numbers obtained as a result of experiments will give a complete understanding of the operation of the resulting formula. And now the developer company Express-24 LLC is confident that if soldering flux residues remain under the replaced microcircuit or SMD components, then the Printed Circuit Board will work, there will be no current leaks, and there will be no corrosion.

Flux consists of organic substances that have been processed and purified to one degree or another. In its composition, each chemical component plays its own important role.

This soldering flux is low activity, which is why it works well in areas where there is no corrosion on the conductors. This is an excellent no-clean solder flux for soldering new Printed Circuit Boards in manufactory, solder DIY and for repairing various electronics PCBs, including wire harnesses. There is no way to wash the flux out from under the wire braid, which means the solder flux under the wire insulation will remain forever and it should not cause harm to the wire - this is the most important indicator.

We also thought about the packaging and understand that when transporting soldering flux in syringe, its packaging may be damaged, and for this purpose the syringe was packed in a vacuum package, which also contains a needle for the syringe.

Since the soldering flux is produced in the United States, its cost price is quite high. The competition is at the highest level and we are very pleased to take part in an honest quality relay race for customers. We will be happy to answer your questions if any difficulties arise during the soldering process. Feel free to contact e-mail for any technological difficulties! We have extensive experience in the electronics PCBs production and repair of electronics, in technical processes on any equipment for the manufactory and repair of Printed Circuit Boards.

The research lasted about 1 year with 17 serious experiments and an insane number of small tests were done.

To create a solder flux for soldering electronics, a number of requirements must be taken into account, and each requirement is very important.

Some of the requirements: No halogens, no current leakage, corrosion resistance, operating temperature range, boiling points, no smoke during soldering, toxicity indicators, harm to the environment and people, shelf life, easy cleaning and many other indicators that are no less important.

To achieve stable performance, it is necessary to carefully select chemical components, calculate formulas and molar masses. Each iteration of the soldering flux formula must undergo a series of checks and tests. The tests also require equipment that was purchased. Only numbers obtained as a result of experiments will give a complete understanding of the operation of the resulting formula. And now the developer company Express-24 LLC is confident that if soldering flux residues remain under the replaced microcircuit or SMD components, then the Printed Circuit Board will work, there will be no current leaks, and there will be no corrosion.

Flux consists of organic substances that have been processed and purified to one degree or another. In its composition, each chemical component plays its own important role.

This soldering flux is low activity, which is why it works well in areas where there is no corrosion on the conductors. This is an excellent no-clean solder flux for soldering new Printed Circuit Boards in manufactory, solder DIY and for repairing various electronics PCBs, including wire harnesses. There is no way to wash the flux out from under the wire braid, which means the solder flux under the wire insulation will remain forever and it should not cause harm to the wire - this is the most important indicator.

We also thought about the packaging and understand that when transporting soldering flux in syringe, its packaging may be damaged, and for this purpose the syringe was packed in a vacuum package, which also contains a needle for the syringe.

Since the soldering flux is produced in the United States, its cost price is quite high. The competition is at the highest level and we are very pleased to take part in an honest quality relay race for customers. We will be happy to answer your questions if any difficulties arise during the soldering process. Feel free to contact e-mail for any technological difficulties! We have extensive experience in the electronics PCBs production and repair of electronics, in technical processes on any equipment for the manufactory and repair of Printed Circuit Boards.