Soldering Joints Corroded on PCB after Assembling and Cutting

Author Dmitrii KhramtsovPosted 22 October 2025

Updated 03 November 2025

PCB Assembling

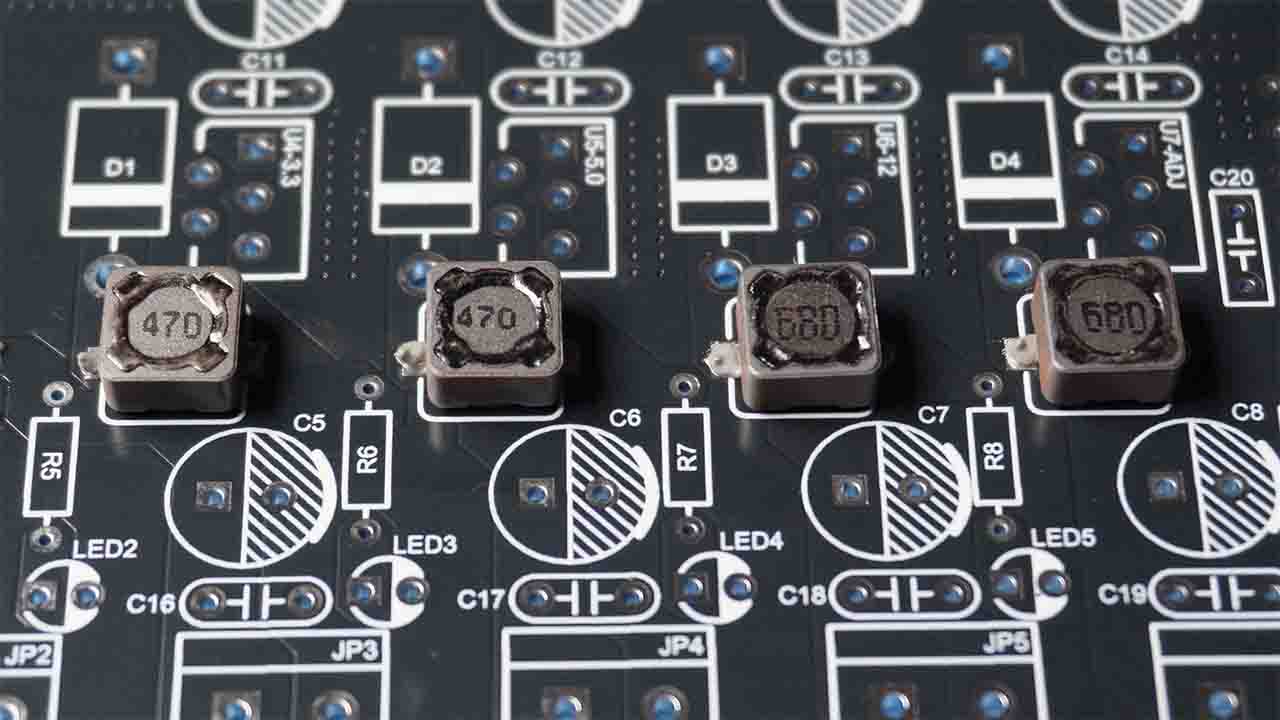

I assembled a printed circuit board that included both surface-mount (SMD) and through-hole (DIP) components — this method is called mixed mounting technology.

To reduce manufacturing costs and assembly time, you or your designer can redesign your PCB to minimize manual soldering of DIP components and replace them with SMD versions wherever possible. A PCB with only SMD components, including connectors, can be assembled and soldered much faster on automated production lines.

PCB Soldering Setup and Conditions

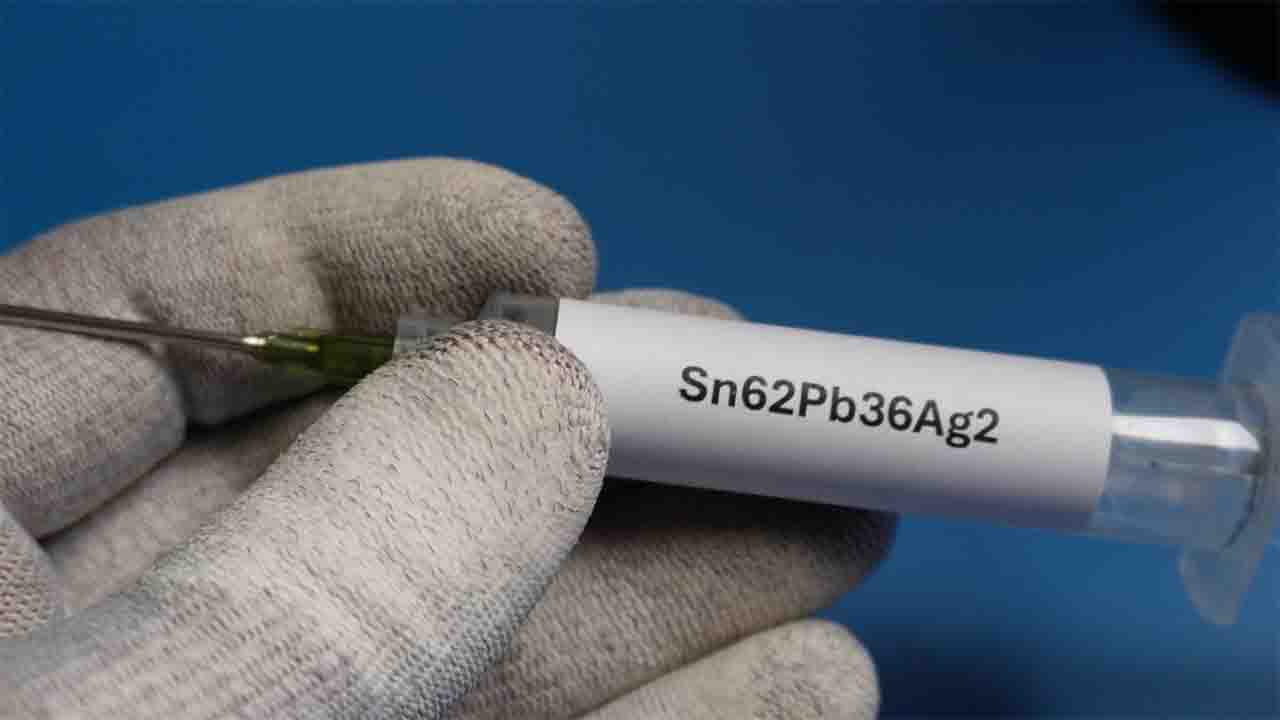

SMD components were placed on Sn62Pb37Ag2% solder paste and reflowed using a bottom preheater plate. The PCB was laid directly on the hot plate at 200 °C (392 °F).

Since the melting point of leaded solder starts at 183 °C (361 °F), this temperature is more than sufficient. This approach is suitable for small-batch or one-off projects and is cost-effective for manual work.

The DIP components were installed into their holes and the leads were bent on the opposite side of the PCB to prevent them from falling out during soldering.

Soldering Fluxes and Solder Wire Used

Soldering Fluxes I used:

- Diamond Flux FN231 — gel soldering flux in syringe, also no-clean ROL0.

- Diamond Flux FN232 — liquid soldering flux, brush-applicator, no-clean, class ROL0.

Solder Wire I used:

- Sn63Pb37 leaded solder wire, 0.8 mm diameter, soldering iron tip temperature 320 °C (608 °F).

Always double-check component polarity and orientation according to silkscreen or assembly drawings before soldering.

After soldering, I clipped all the DIP leads flush with the board.

What Is THT and DIP?

THT - Through-Hole Technology is the method of mounting leaded components through drilled holes.

DIP - Dual-In-Line Package describes the package type — two parallel rows of pins intended for through-hole insertion. A DIP component is therefore one type of THT component.

Emulating wet conditions for printed circuit boards

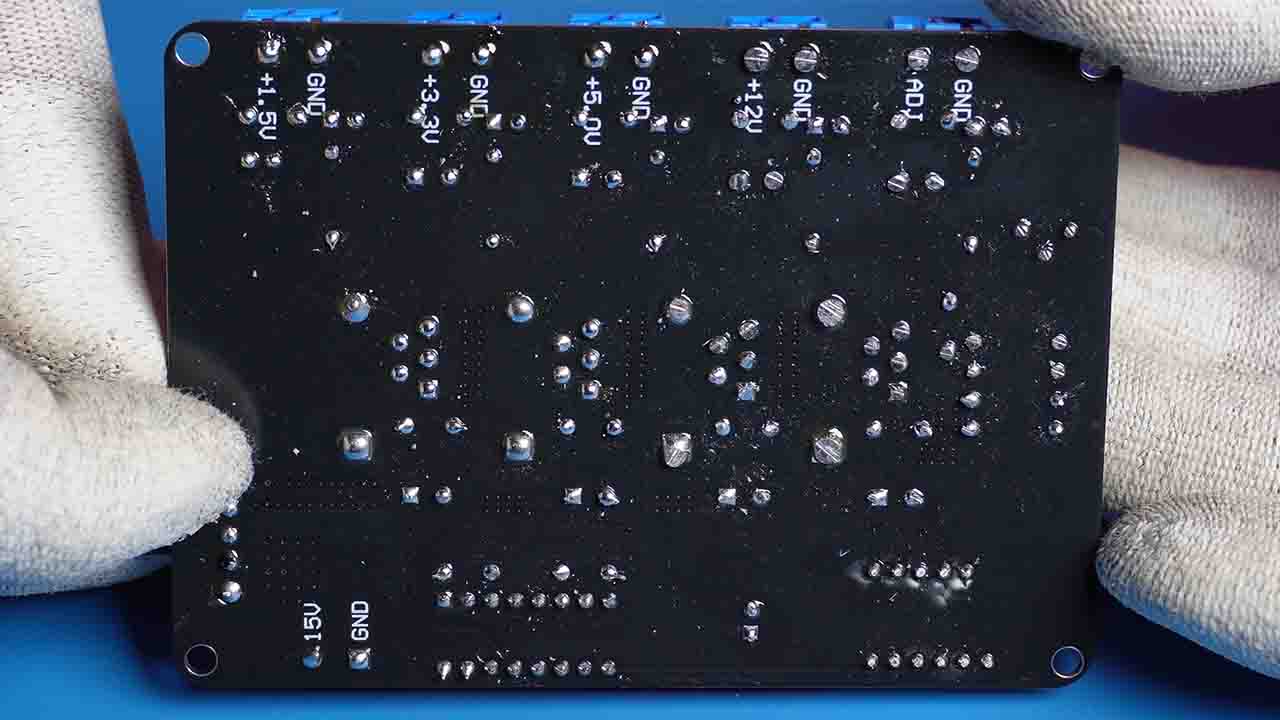

To demonstrate a common mistake, I intentionally made two different sections on the PCB:

- On one half of PCB, I re-soldered the cutted DIP leads.

- On the other half of PCB, I left the DIP leads un-soldered, exposing the base metal.

After that, I cleaned the PCB using Flux OFF cleaner.

To simulate real operating conditions — such as salt mist near oceans or morning condensation — I prepared a salt solution: half a teaspoon of table salt per glass of warm water.

I repeatedly wetted and dried the soldered areas to simulating natural humidity cycles without powering the board. This procedure realistically imitates what happens in non-sealed housings or coastal environments with daily temperature changes.

Why does rust appear on unsoldered soldering joints?

The difference was clear:

- The re-soldered leads remained clean and intact.

- The clipped, un-soldered leads showed visible rust and corrosion.

When DIP leads are cut, the exposed soldering joints internal metal is left unprotected. In many cases, soldering joints core material contains iron or iron-nickel alloys, which oxidize rapidly in the presence of moisture.

Other leads, made of copper, brass, or bronze, did not corrode under the same conditions.

What Are DIP Lead Metals Made Of?

The base materials for DIP leads can vary — copper, aluminum, steel, brass, bronze, or Fe-Ni alloys.

Typically, they are coated with:

- Nickel barrier layer — ensures adhesion between the base metal and outer finish coating.

- Final solderable finish coating — usually a lead-free tin alloy, providing good solderability.

However, datasheets rarely specify the core metal composition — only the outer plating. Therefore, you cannot reliably predict which components will rust after soldering.

How to Prevent Through-Hole DIP Leads Corrosion?

- After cutting the DIP leads, always re-solder soldering joints and tin the exposed leads to seal the base metal from air and moisture.

- Avoid leaving bare metal exposed after cleaning.

- Store Printed Circuit Boards in a dry cabinets, especially before applying a protective coating.

- To prevent rust and oxidation on devices operating outdoors and in humid environments, use sealed enclosures.

Why is proper PCB assembly and soldering important?

Corrosion gradually eats into the lead, often between internal metal layers, causing hidden fractures and open circuits. Over time, this may lead to device failure or customer complaints about quality.

In production, visible corrosion is unacceptable and may require re-soldering and additional cleaning, increasing both labor and material costs.

Thank you for reading!

Watch video Soldering Joints Corroded on PCB after Assembling and Cutting