What's the Difference Between Solder Paste and Soldering Flux?

Author Dmitrii KhramtsovPosted 12 January 2026

Updated 12 January 2026

Solder Paste and Soldering Flux

It’s not the same thing - they are different materials.

Solder paste and Soldering flux are often confused, but they have different purposes.

Solder Paste

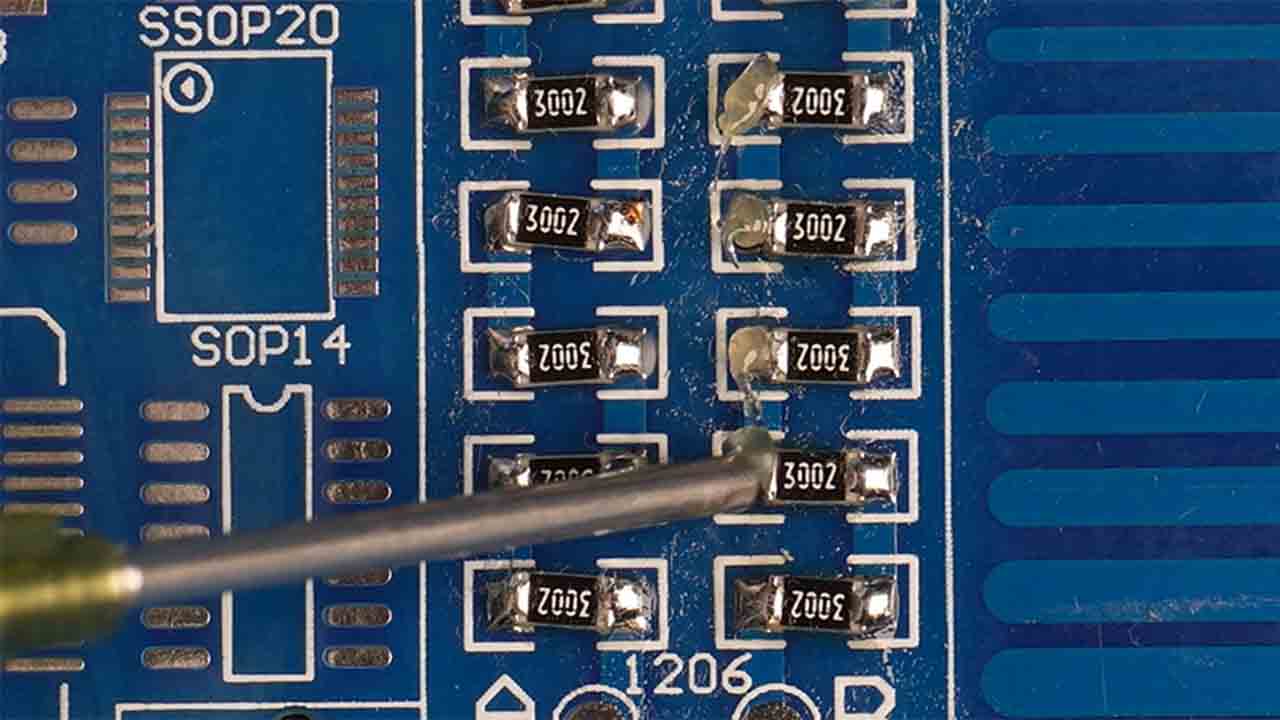

Solder paste is a mixture of very small metal balls of leaded or lead-free solder alloy, dark gray in color, with soldering flux as a part of mixture. During reflow, the small metal balls melt, forming molten liquid metal that connects the electronic components and the printed circuit board, creating a solder joints.

Solder paste is used for soldering electronic components to the printed circuit boards in manufacturing and repair shops. In manufacturing, solder paste is applied through a stencil directly to the printed circuit boards. Then a pick-and-place machine place electronic components onto the solder paste. At the next step, the printed circuit boards moving into reflow oven, where the solder paste begins to melt, reliably connecting all electronic components with printed circuit boards. In repair shops solder paste usually using for reballing microchips.

Solder paste is not intended for soldering with a soldering iron, because it designed for reflow in oven or with hot air. You can learn more about solder paste in this article - SOLDER PASTE.

Soldering Flux

Soldering flux is a chemical composition made of various organic or synthetic resins with many additives and acids. The color can be yellow, orange, brown, white or transparent. Flux can be liquid or gel, like you need. Soldering flux can be used separately in a jar or syringe, but it is also necessary included in solder paste as an integral part.

The task of soldering flux is to help molten liquid metal flow more easily during soldering and reflow, allowing the metal to penetrate narrow spaces around the leads of electronic components. Soldering flux also cleans the metal surfaces of component leads and printed circuit board pads from oxide films, which significantly improves soldering quality and adhesion between metals.

Removal of oxide films occurs due to active chemical substances that are part of the soldering flux. Also Soldering fluxes are divided into different classes. I explained flux classification in detail in this article - SOLDERING FLUX CLASSIFICATION.

You simply apply soldering flux to the required area or wires and replace, solder or tinning.

As you can see, solder paste and solder flux are two different substances with different purposes — metal and chemistry.

Thank you for reading!

Watch video What's the Difference Between Solder Paste and Soldering Flux?